To carry out our research, EML is equipped with state-of-the-art equipment to characterize polymers, composites, and smart materials.

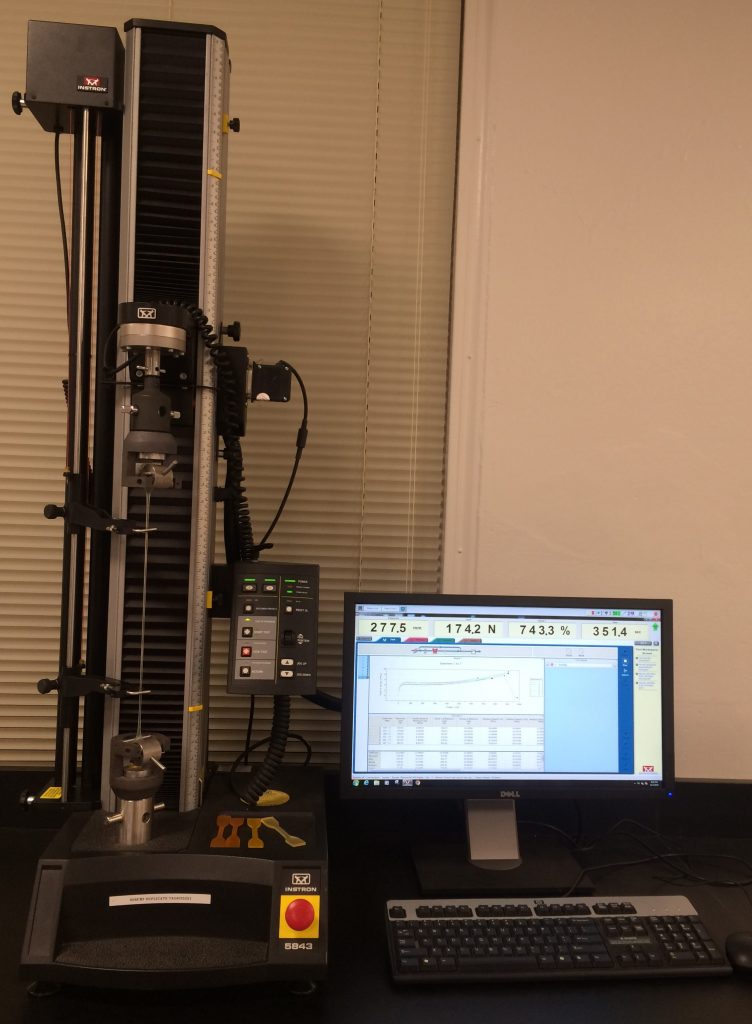

EML is equipped with 1kN load frame for testing of Adhesion, Compression, Ductility, Fatigue, Shear or Torsion, Tensile, Flexure or Bending of polymers and composite materials. The specimen is placed in the machine between the grips and an extensometer if required can automatically record the change in gauge length during the test. If an extensometer is not fitted, the machine itself can record the displacement between its crossheads on which the specimen is held. Instron 5843 has amaximum travel of 1076 mm and speed range from quasi-static to 16.67 mm/sec. To measure strain, the load frame is equipped with calibrated extra-large travel to report strains up to 2500%.

EML is equipped with an MTS 858 Material Testing System capable of static and dynamic testing applications. It uses a servohydraulic system with a load capability of up to 10 kN to characterize a wide range of materials, particularly small components and biomedical materials. Testing modes include tension, compression, bending, fatigue, durability, and user-defined specialized tests for biomedical and biomechanical testing.

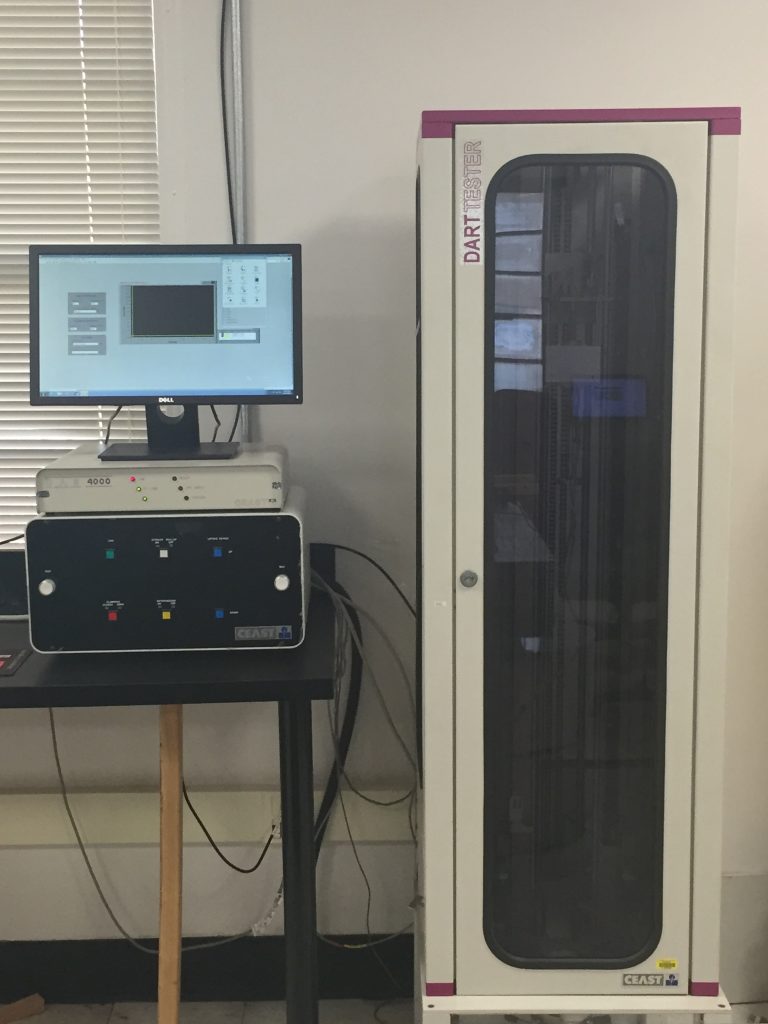

EML is equipped with a floor standing impact system capable of delivering up to 50J of energy. The system configuration is flexible to easily adjust the drop energy by adjusting the weight and/or drop height.

The data acquisition system consists of reflected and transmitted force sensors, 200g accelerometer, and speed sensor and capable to acquire samples at a rate of 125kS/s per channel.

The in-house developed automated data analysis code can extract important characteristics of force-time history, which include rise-time, amplitude, wave duration, etc.

Coupling the system with our expertise in mechanical design, experimentation, and automation, the capabilities of the machine can be easily altered to match new experimental protocols.

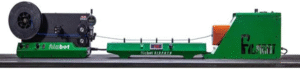

EML has developed a built-in-house shock tube to measure the mechanical characteristics of samples under fast loading. Used in conjunction with the EML’s high speed camera and digital image correlation system, the deformation behavior and stresses of materials can be captured over very short time spans.

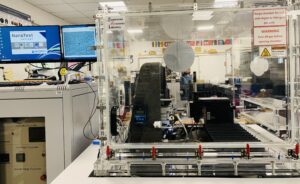

EML is equipped with the Dantec Dynamics MulticamDIC system with the analysis software Istra4D. Digital Image Correlation is a non-contact optical technique that measures the deformation of an object’s surface by tracking the movement of a pattern (speckle) applied to its surface, allowing for precise full-field measurements of displacement and strain across the sample, providing detailed information about how an object deforms under load in various testing scenarios like tensile, compression, or bending. The system can be used in multiple loading scenarios, such as quasi-static testing or impact drop testing.

EML is equipped with a high-speed camera (Fastcam Mini AX200 Type 900k) for imaging high speed impacts using the floor standing drop tower and the shock tube setups. The AX200 can reach 900,000 fps, with a light sensitivity of ISO 50,000 monochrome and a shutter speed of 260 ns. The incredible speed and clarity of the AX200 captures the deformation of samples throughout the deformation process under high speed impacts, and when used in conjunction with the DIC software, can resolve the full-field strain and displacement of the samples.

EML is equipped with two GSVitec LT lamps. The GSVitec LT is a high powered, flicker free continuous light fixture that is a perfect compliment to high speed cameras and can output up to 14,000 lumens. The GSVitec LT is equipped with 24 high power LEDs producing 14,000 lumens. Standard beam angle lenses are at 12° full working angle. A big plus for the MultiLED LT is its versatility with exchangeable lenses with opening angles of 25° x 25°, 40° x 40°, 60° x 60°, 30° x 13°, 60° x 12°.

EML is equipped with a Dynamic Mechanical Analyzer (TA Instruments Discovery DMA 850), which is capable of measuring the mechanical properties of materials as a function of time, temperature, and frequency. DMA is essential for the proposed research. The DMA 850 instrument incorporates unique technology to provide the ultimate in performance, versatility, and ease-of-use. State-of-the-art non-contact, linear drive motor technology in the DMA instruments provides precise stress control. Ultra-sensitive optical encoder technology is used to measure strain, and air-bearing technology ensures virtually friction-free movement. The combination of these technologies sets the DMA 850 apart from competitive instruments that use conventional stepper motors, LVDT strain measurement devices, and mechanical springs. The DMA 850 instrument operates over a wide temperature range (-180 to 550°C) and provides multiple modes of deformation including dual/single cantilever and 3-point bending, tension, and compression, all of which are available at EML.

EML is equipped with a Thermogravimetric Analyzer (TA Instruments Q50), which integrates mass flow control, gas-switching capability, superb software, and ease-of-use, making the Q50 ideal in basic research. The Q50 can be used in polymer and composite materials compositional analysis, filler content, and moisture content and thermal stability. It provides Temperature Control and Measurement, accurate and precise purge gas metering, Thermobalance with one of the best accuracy and precision in weight change detection from ambient to 1 000˚C, low baseline drift, and sensitive, reliable operation over the entire weight range. An efficient horizontal purge gas system allows accurately metered purge gas to flow directly across the sample, and is expertly integrated into the vertical thermobalance/furnace design.

EML is equipped with a Differential Scanning Calorimeter (TA Instruments DSC25). The DSC25 can be used in polymer and composite materials compositional analysis, thermal transition characterization, and thermal stability. It provides temperature control and measurement, accurate and precise purge gas metering, and the patented Tzero technology which measures cell resistance and capacitance characteristics and delivers fundamentally more accurate heat flow measurement. The DSC25 is also capable of modulated DSC, allowing for increased sensitivity in thermal transition measurement and characterization.

EML is equipped with a TA Instruments HR20 Discovery Hybrid Rheometer, which is capable of measuring the storage and loss shear moduli of materials and liquids as a function of temperature, shear rate, strain, and stress. The HR20 incorporates TA’s patented Magnetic Thrust Bearing which reduces basic system friction by 70% compared to traditional designs, ensuring virtually friction-free movement. Additional geometries provide multiple modes of testing, including dual/single cantilever and 3-point bending, tension, and compression, all of which are available at EML.

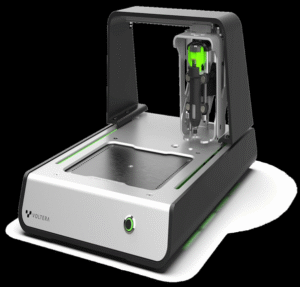

EML is equipped with a nanoindenter (Micro Materials NanoTest Vantage). The nanoindenter is capable of indentation, impact, scratch, fatigue, and AFM modes across the nano and micro force scales. A variety of test can be preformed, including repeated impacts/indents of constant or varying forces, creep tests, and more. Impact and indent force ranges from 5 μN to 30 N. A wide variety of mechanical properties can be determined. EML is also equipped with the gas purge chamber allowing for the control of temperature up to 850 °C, humidity, and the use of purge gasses.

EML is equipped with a nanoindenter (Micro Materials NanoTest Vantage). The nanoindenter is capable of indentation, impact, scratch, fatigue, and AFM modes across the nano and micro force scales. A variety of test can be preformed, including repeated impacts/indents of constant or varying forces, creep tests, and more. Impact and indent force ranges from 5 μN to 30 N. A wide variety of mechanical properties can be determined. EML is also equipped with the gas purge chamber allowing for the control of temperature up to 850 °C, humidity, and the use of purge gasses.

EML is equipped with Atomic Force Microscopy (AFM WORKSHOP TT-AFM), which is capable of scanning large samples. The TT-AFM is a complete system and includes everything required for scanning all sizes and shapes of samples. The three-dimensional motion of the sample is generated by piezoelectric ceramics, these sensitive ceramics allow motions as small as fraction of a nanometer. Typically, the sample is moved in a raster patterns as the probe glides across the surface. A light lever sensor is used for controlling the force of the probe on the surface while the sample is scanned. All standard scanning modes are included on AFM installed in the lab. Vibrating mode can be used for high resolution and soft samples, while non-vibrating mode can be used for routine scanning. The AFM is equipped with phase and lateral force, force-displacement, MFM, and C-AFM modes.

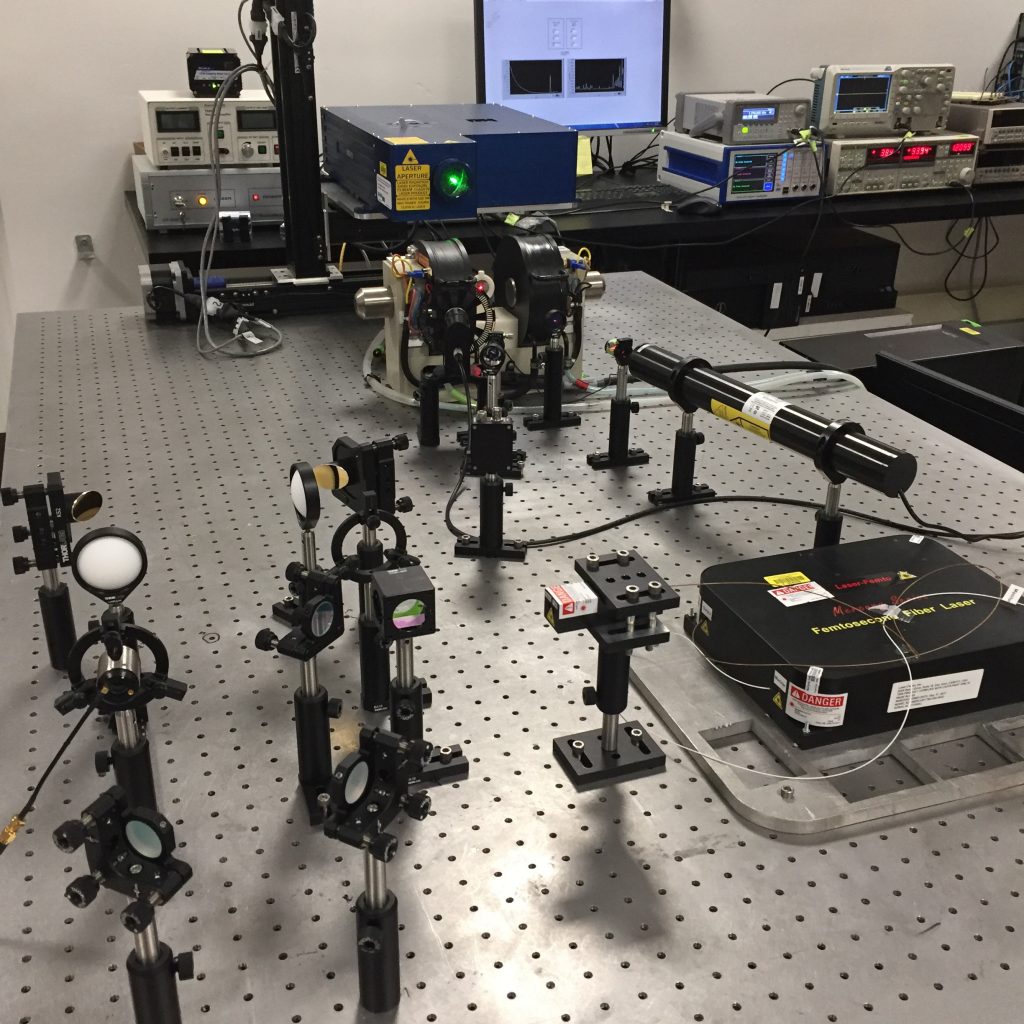

EML has developed a built-in-house multimode terahertz time-domain spectroscopy setup, including separately operated transmission and reflection configurations. The setups can be used for single-point or mapping investigations with up to 3.5 THz bandwidth.

EML is equipped with a magneto-optic Kerr effect (MOKE), which is one of the magneto-optic effects. It describes the changes to light reflected from a magnetized surface. It is used in materials science research in devices such as the Kerr microscope, to investigate the magnetization structure of materials.

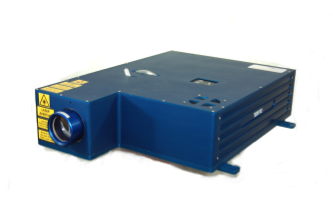

EML is equipped with a high-power femstosecond laser (ELMO 780 HP). It delivers extremely short concentrated bursts of light at a wavelength of ~780 nm, simulating incredibly high speed impacts (~20,000 m/s). The pulse width is ~85 fs and the power is ~165 mW.

EML is equipped with a multi-component laser receiver, capable of simultaneously measuring two components of the surface displacement, the out-of-plane and the in-plane motions, using a single laser probe and a single collecting optic. The detection of the in-plane component allows efficient detection of shear waves, particularly when the direction of ultrasounds propagation is normal to the surface of inspection. The TEMPO 2D has a internal laser power of 500mW @532nm, 20MHz detection bandwidth and NESD (out-of-plane motion) of 2 x 10-7 nm (W/Hz)1/2.

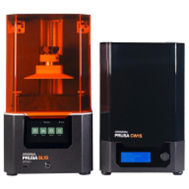

EML has an Original Prusa SL1S SPEED+ multifunctional device for processing resin (CW1S Machine). This printer uses a high-resolution (MONOCHROME) LCD panel and a UV LED array to cure thin layers of resin to achieve an unprecedented level of detail. It is compatible with a wide range of resins for various applications. It is capable of 3x faster layer printing, 1.4 seconds/layer, and a large working volume – 127 × 80 × 150mm.

EML is equipped with the Creality HALOT-MAGE 8K, a resin 3D printer that can be used for producing high quality, fine resolution prints prints. The HALOT-MAGE has a build volume of 228 x 128 x 230 mm and a minimum layer height of 50 microns. This printer uses an 8K mono LCD to achieve an incredible 30 micron XY resolution, allowing for extremely detailed prints and features with high precision.

EML is equipped with the Creality K1, a high-speed FFF 3D printer that can print a variety of materials and can be used for both rapid prototyping and producing high quality prints. With a multi-fan enclosure, the cooling of the part can be finely controlled for defect control. The K1 has a build volume of 220 x 220 x 250 mm, a max printing speed of 600 mm/s, and a minimum layer height of 100 microns.

EML is equipped with the Anycubic Photon Mono 2, a resin 3D printer that can be used for producing high quality, fine resolution prints prints. The Photon Mono 2 has a build volume of 165 x 143 x 89 mm and a minimum layer height of 35 microns. This printer uses a high-resolution parallel matrix light source to cure thin layers of resin, allowing users to print intricate and customized designs with high precision.

EML is equipped with a desktop FFF 3D printer, designed to work with demanding materials such as PEEK and ULTEM. It can build a volume of 260 × 260 × 260 mm. This printer features enclosed chambers that allow them to work in high temperatures. The printer will save print during power loss. The extruder can reach a temperature of 400 °C.

EML is equipped with a uPrint, a professional grade 3D printer from Stratasys that utilizes ABSplus to produce high quality models and prototypes. The build volume is 20.3 x 15.2 x 15.2 cm and the minimum layer thickness is 254 microns. Its highly advanced, powerful, stable platform is made to work seamlessly with CAD software.

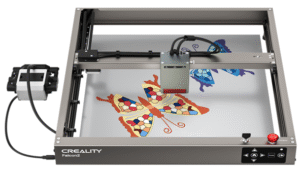

EML is equipped with a Voltera V-One, a PCB printer than can also use conductive and other direct ink writing inks. This allows the EML to create their own DIW films and structures out of a variety of inks and solutions.

EML is equipped with a rotary microtome (Leitz 1512) that allows the lab to carefully slice and section a variety of samples for microscopic characterizations and other testing methods. THe 1512 has a minimum thickness adjustment of 1 micron.

EML is equipped with Atomic Force Microscopy (AFM WORKSHOP HR), which is capable of scanning samples up to 2500 microns square. The HR is a complete system and includes everything required for scanning all sizes and shapes of samples. The three-dimensional motion of the sample is generated by piezoelectric ceramics, these sensitive ceramics allow motions as small as fraction of a nanometer. Typically, the sample is moved in a raster patterns as the probe glides across the surface. A light lever sensor is used for controlling the force of the probe on the surface while the sample is scanned. All standard scanning modes are included on AFM installed in the lab. Vibrating mode can be used for high resolution and soft samples, while non-vibrating mode can be used for routine scanning. The AFM is equipped with phase and lateral force, force-displacement, MFM, and C-AFM modes.

EML is equipped with a high-magnification digital optical microscope (Keyence VHX-7000). Fitted with lenses allowing for magnifications of up to 2500x, the VHX-7000 give the EML the ability to capture high quality 4K images of samples. The VHX-7000 also contains an adjustable tilt for the microscope and a computer controlled sample bed with 4 degrees of freedom. The lenses are equipped with full and partial axial and ring lighting, allowing for a wide array of lighting conditions. The Keyence software can perform depth compositions, identifying the height of contours of samples, allowing for 3D reconstruction of the sample surface. Other features such as image stitching, glare removal, multi-lighting capture, and feature measurement are also available for the EML.

EML is equipped with a state-of-the-art ultrasonic measurement system (Olympus) to deduce the elastic moduli and Poisson’s ratio of polymers. Ultrasonic techniques have been used because wave velocity depends on the elastic properties of the propagation medium. The system has two sets of ultrasonic transducers; namely pressure and shear, which can be configured in either pitch-catch or thru-transmission configurations. The pulser-receiver unit is capable of generating square wave excitation, which is required in applications involving the testing of thick or highly attenuating materials, such as polymers, with low-frequency transducers.

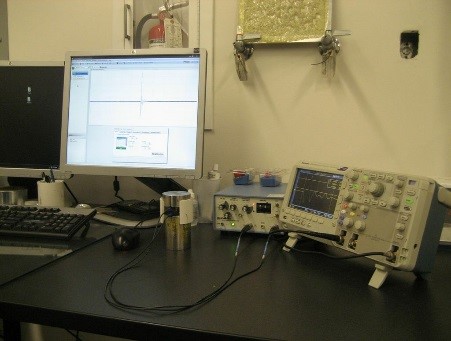

EML is equipped with a fully automated state-of-the-art multiferroic testing and characterization experimental setup. It consists of an electromagnet (GMW Associates 3470 Dipole), high voltage amplifier (TREK PZD700A Dual Channel), function generator (Agilent 33210A), digital oscilloscope (Tektronix DPO2012), lock-in amplifier (Stanford Research Systems SR830 DSP), and data acquisition board (Measurement and Computing PCI-DAS 1602/12). The electromagnetic interference (EMI) is reduced by enclosing the testing chamber with high permeability shield. The setup is capable of applying voltage up to ±700V at different frequencies up to 120kHz, while applying a maximum magnetic field of 2500Oe.

EML is equipped with a Filabot EX2 Extruder Setup, which is a material conversion tool that opens new opportunities in 3D printing by enabling efficient plastic recycling and innovative use of plastics. It provides a small-scale solution to a significant environmental challenge, making sustainable manufacturing accessible to a broader audience, including those without expert knowledge. This closed-loop system exemplifies sophisticated engineering, condensing an entire filament production line into three key components: the EX2 Extruder, Airpath, and Spooler. The setup also allows the EML to design and produce our own custom filaments for experimentation and testing.

EML is equipped with a sputter coater (Emitech K575X) to create and prepare samples for testing. The K575X system uses a magnetron target assembly combined with a turbo molecular pump and rotary vacuum pump to coat samples on a 57 mm diameter rotating bed. It is able to carry out sputter cleaning and sputter coating cycles.

EML is equipped with a Spin Coater (Laurell WS-650MZ-23), which uses a rotating system to evenly distribute liquids across a substrate. The 650 series utilizes a robust microprocessor with the accompanying Spin3000 software to achieves nearly unheard of flexibility both in process definition and use. This controller allows operator interaction in real-time during the process execution including pausing time, stopping and continuing on from that point. It has fully customizable spin programming, allowing for multiple spin steps to be entered. It can handle 150mm diameter wafers and 127 × 127 mm substrates, and features a maximum rotational speed of 12,000 RPM.

EML is equipped with a nitrogen generator (Parker UHPN2-1500C-W) with a wide range of uses, from providing an inert environment for printing sensitive resins to use in drying and removing moisture from samples and base materials.

EML is equipped with a Diamond Saw Buehler IsoMet Low Speed cutting machine is a precision sectioning saw that is designed for cutting various types of materials with minimal deformation. This low speed precision cutter is targeted for delicate parts by only using gravity fed force. Low speed sectioning tool capable of cutting virtually any material including brittle or ductile metals, composites, cements, laminates, plastics, electronic devices and biomaterials. It provides gravity fed cutting force to reduce deformation on delicate samples, precise cut location control and great versatility in sample holders for all shapes and configurations of cuts required.

EML is equiped with a ultrasonic cleaner/mixer. The Crest CP1100HT Ultrasonic Cleaner is a 0.75 gallon cleaner that is equipped with a Digital display for a 0-30 minute timer and thermostat that goes up to 175 degrees Fahrenheit (80 degrees Celcius). Cleans at an ultrasonic power of 80 watts on average at a frequency of 42 – 45 kHz and ensures uniform cleaning throughout the tank by sweeping the ultrasonic frequency 3 kHz, creating overlapping ultrasonic waves.

EML is equipped with a centrifuge (Yescom 800-1). With a maximum rotational speed of 4000 rpm, it is used for separating liquids of different densities or precipitates from solutions.

EML is equipped with a centrifugal planetary mixer (Thinky AR-100), which can efficiently mix, disperse, and deaerate small amounts of material. It uses a disposable container (100ml) as the Standard Container and has a maximum capacity of 140g. The EML uses it to create new resins and solutions for use in 3D printing and other applications.

EML is equipped with a Scilogex MS-H280-Pro Digital Hotplate Stirrer. It is a very economically priced LED digital hotplate-stirrer ideal for handling small volume task on daily application, as a low temperature magnetic stirrer with max. temperature at 280°C. This compact unit can be used as a hotplate, stirrer or combination.

EML is equipped with a JJ-1 Precise Strength Power Mixer. This mixer allows for the careful mixing of sample solutions at specific speeds and powers exceeding those that the hotplate stirrer is capable of.

EML is equipped with the Buehler MetaServ 250, a grinder-polisher featuring a rotating base with a speed of up to 500 rpm. The MetaServ 250 is used to precisely grind and polish material samples, typically metal specimens, to a smooth, flat surface for analysis under a microscope, allowing for detailed examination of the sample’s microstructure.

EML is equipped with a 12-Ton Strongway Hydraulic Shop Press. The press can be used for straightening, stamping, bending and pressing any sample or component. Additionally, the press allows for the formation of solid samples out of powders and other similar sample preparations.

EML is equipped with a gravity convection oven (Lab Safety Supply 32EZ28) with a maximum temperature of 200 °C. It has a wide variety of uses, from sample heating and drying to sterilization and more

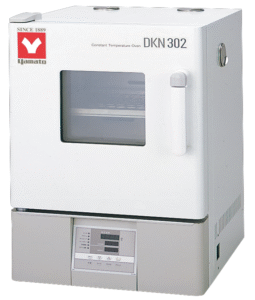

EML is equipped with a forced convection oven (Yamato Scientific DKN302C) with a maximum temperature of up to 260 °C. With fully programmable temperature and timings, it can maintain a precise, set temperature within its chamber, allowing for consistent heating and drying of materials in a laboratory setting, making it ideal for applications where precise temperature control is crucial, like sample drying or curing processes.

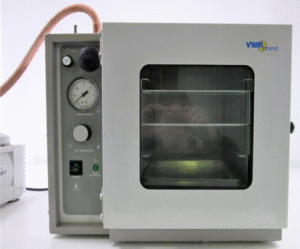

EML is equipped with a vacuum oven (VWR Scientific 1410 Vacuum Oven) that can effectively remove moisture from a substance by combining heat with a reduced pressure environment, allowing for drying of heat-sensitive materials at lower temperatures, making it ideal for delicate samples and materials.

EML is equipped with a high intensity illuminator (Dolar-Jenner Fiber-Lite MI-152 High Intensity Illuminator), that provides high intensity, even light for a variety of purposes, including as an illumination source for DIC used in conjunction with the Instron 5843.

EML is equipped with an LED illuminator (AmScope LED-2M-YA Illuminator) for use in lighting a wide range of scenarios, from supplemental light for optical imaging to additional angles for DIC imaging.

EML is equipped with a Glendan Light Box, allowing for the capture of high-quality images of samples and more for publication.